Manufacturing and industrial sectors operate based on several standards set by local and global governing bodies. The services they provide, the process, and the end products must strictly adhere to standards and norms. Acrylic industrial products facilitate the manufacturing process. They can also serve as state-of-the-art end products intended for use across various industrial departments. Acrylic sheets are used to make enclosures, safety shields, machinery, and lab equipment. Dairy, agro-foods, pharmaceuticals, automotive, and many more industries extensively use acrylic equipment and components. Products like acrylic storage bins or clear tubes are versatile for usage across industries. Acrylic is used for specific requirements like beakers and test tubes for science labs in schools and colleges. Acrylic provides easy covering and storage options for sensitive industrial machinery, sparing frequent maintenance and cleaning. Learn more about our industrial product offerings to see what categories suit your industry best.

Advantages of Acrylic Industrial Products

Acrylic or plexiglass is an industrially manufactured thermoplastic that has a transparent appearance like glass. However, it is durable and does not break when carrying heavy loads or in high temperatures. Acrylic reflects UV light and does not react with chemicals. So, acrylic becomes a natural choice when designing safety equipment like eye masks and shields in hazardous laboratories. Acrylic is also fire-resistant, making acrylic shields and helmets a critical fire-safety accessory. Acrylic covers and equipment do not get damaged in case of fire accidents. Machinery is prone to accumulate dust and rust over time. Acrylic conveyor belt covers and display units prevent dust accumulation, thereby increasing the life of high-grade industrial products. Transparent acrylic panels act as a protective layer over electrical units and prevent fire accidents. Due to their unbreakable properties, acrylic industrial products are the best choice for transporting products from manufacturing units to commercial shops. Acrylic egg trays, bottle holders, and ventilated poultry or meat cases are the best examples.

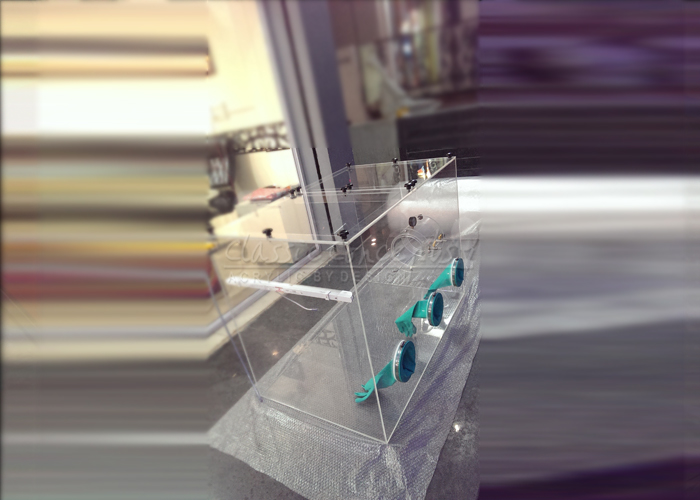

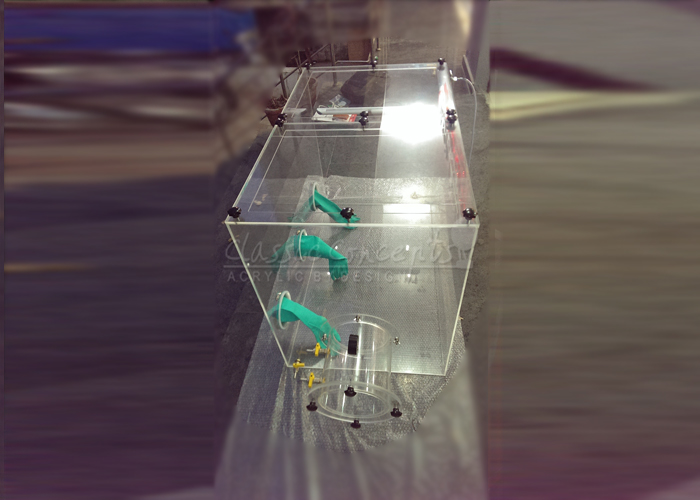

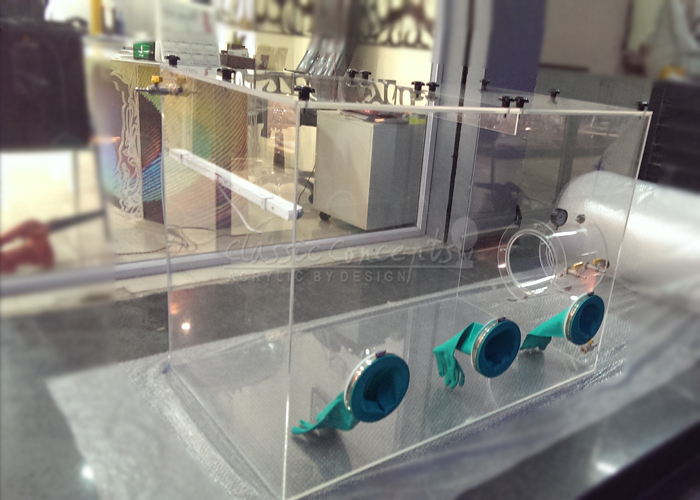

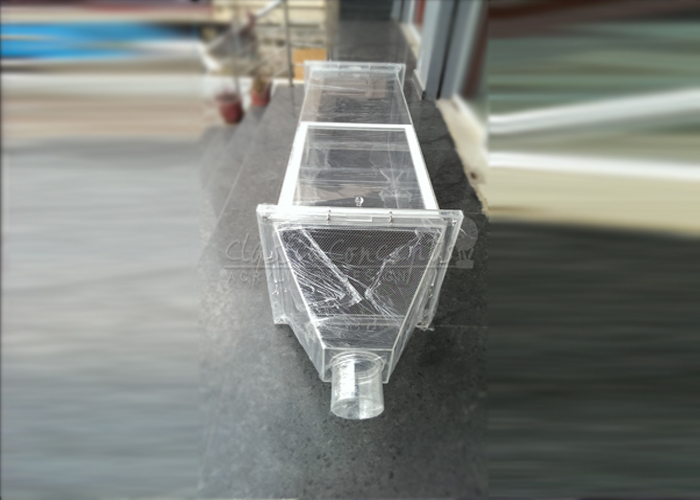

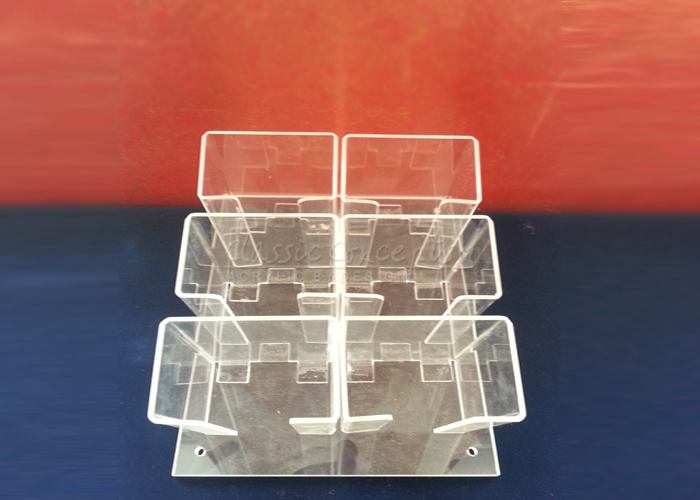

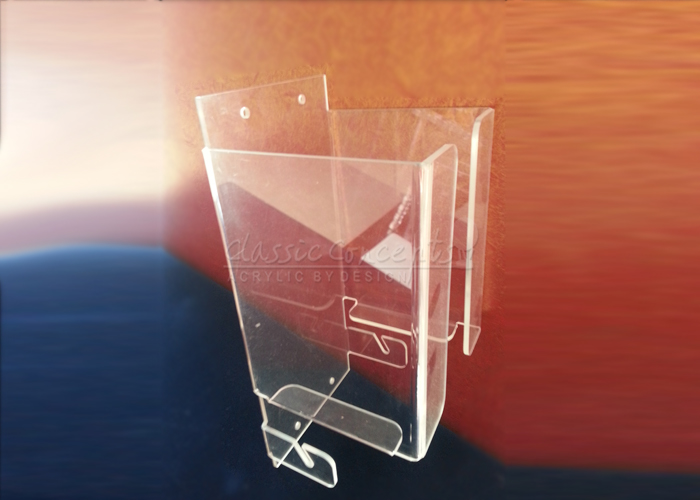

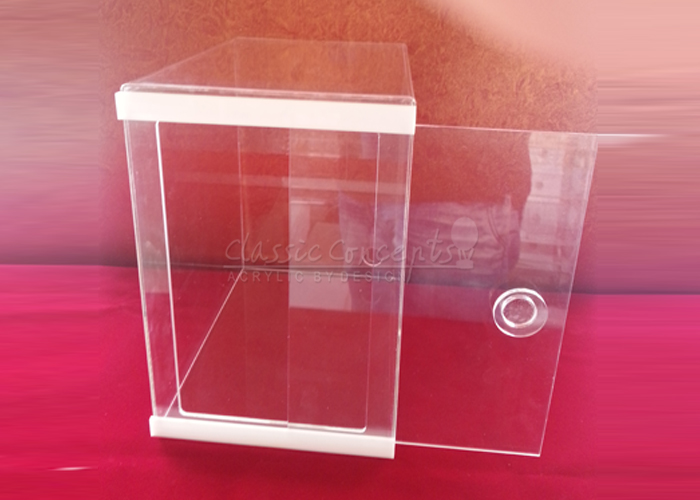

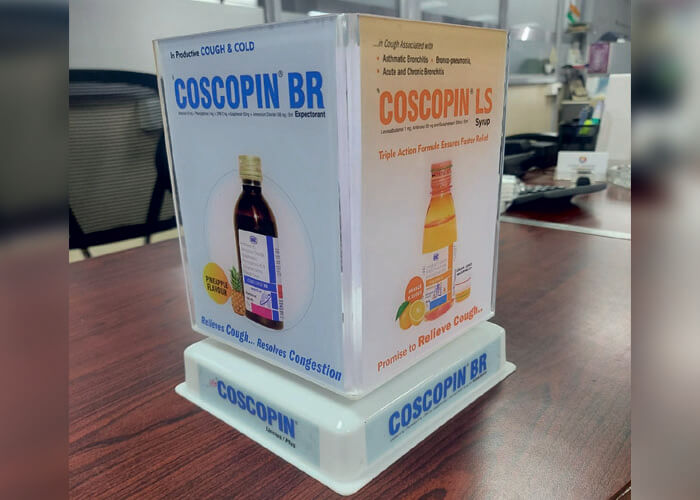

ACIN-MD1

ACIN-MD2

ACIN-MD3

ACIN-MD4

ACIN-MD5

ACIN-MD6

ACIN-MD7

ACIN-MD8

ACIN-MD9

ACIN-MD10

ACIN-MD11

ACIN-MD12

ACIN-MD13

ACIN-MD14

ACIN-MD15

ACIN-MD16

ACIN-MD17

ACIN-MD18

ACIN-MD19

ACIN-MD20

ACIN-MD21

ACIN-MD22

ACIN-MD23

ACIN-MD24

ACIN-MD25

ACIN-MD26

ACIN-MD27

ACIN-MD28

ACIN-MD29

ACIN-MD30

ACIN-MD31

ACIN-MD32

ACIN-MD33

ACIN-MD34

ACIN-MD35

ACIN-MD36

ACIN-MD37

ACIN-MD38

ACIN-MD39

ACIN-MD40

ACIN-MD41

ACIN-MD42

ACIN-MD43

ACIN-MD44

ACIN-MD45

ACIN-MD46

ACIN-MD47

ACIN-MD48

ACIN-MD49

ACIN-MD50

ACIN-MD51

Types of Acrylic Industrial Products

Industrial products act as manufacturing aids and end products to serve other industries. Such products are versatile for industrial and commercial use. Contrary to popular opinion, modern acrylic manufacturing equipment and acrylic machine components are affordable for small and large-scale industries. Let us see the various categories of acrylic industrial products used in manufacturing and commercial establishments.

Clear Acrylic Tubes

Transparent acrylic material provides a radiant lighting effect when light falls on it. This feature makes acrylic the most preferred element for tube lights anywhere. You can cut acrylic tubes, drill, and fix them in any size and diameter. Since plexiglass is UV resistant, the output light from clear acrylic tubes does not harm anyone in the vicinity. Acrylic tubes also act as a medium for conveying fluids. Science laboratories are filled with transparent acrylic tubes to display complex chemical reactions without fear of hazards and breakage. Clear acrylic tubes are versatile to fit any environment. They can act as decorative interior elements, as room dividers, pathway decorations, display stands, etc. You may carve your brand's logos or minimal designs on such tubes to give them a unique touch.

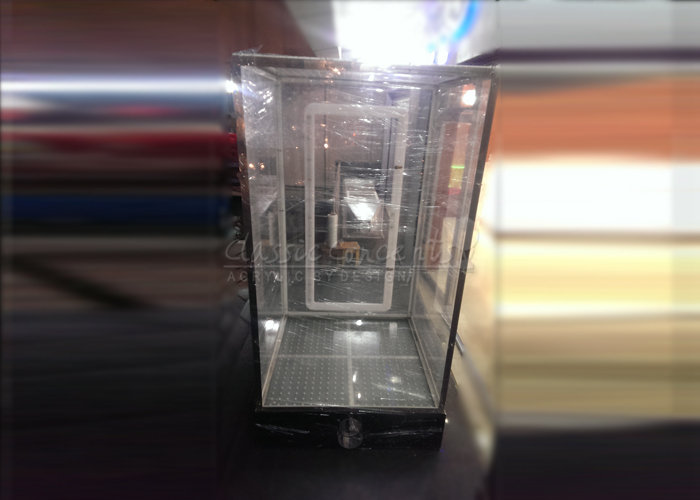

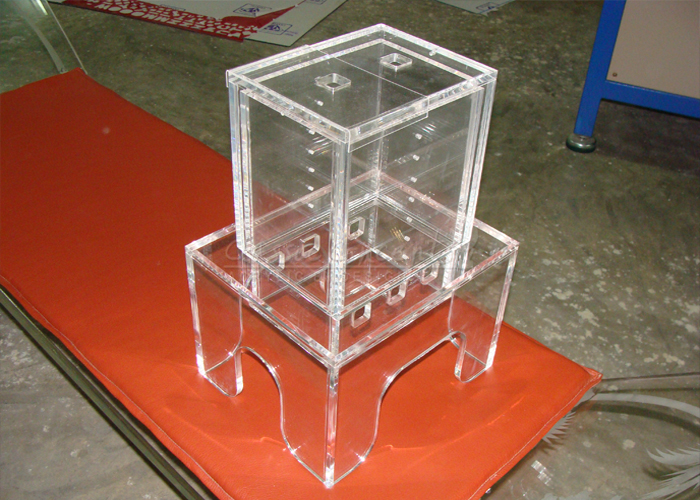

Lucite Machine Guards

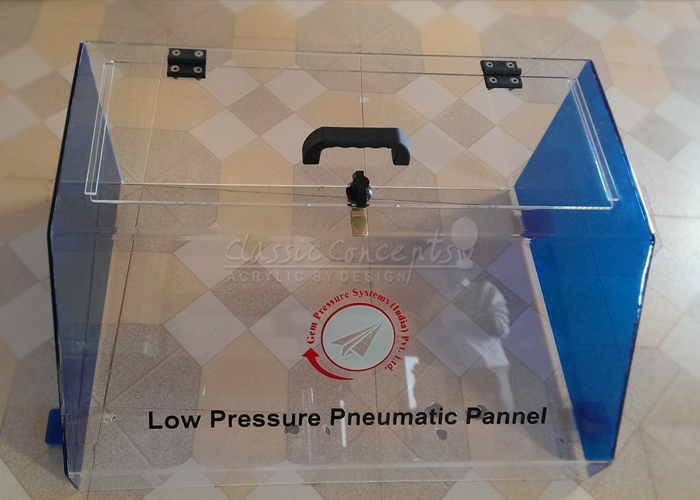

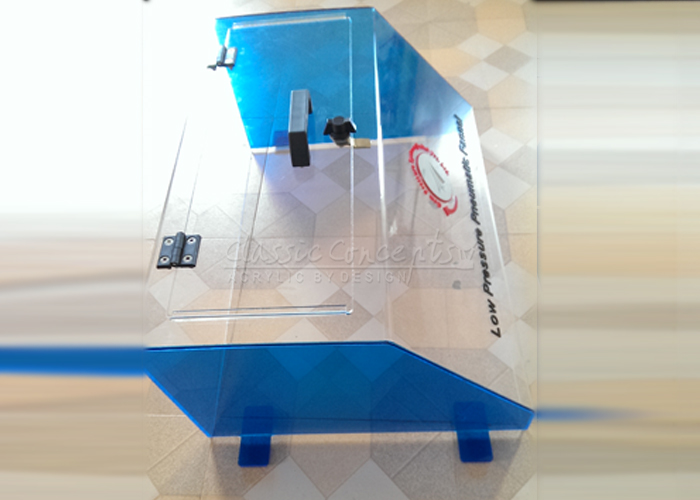

A higher grade of acrylic is lucite, which is comparatively more sturdy than plexiglass. Many industries prefer customizable lucite enclosures for machinery because of this reason. Thanks to its high-grade temperature and fire resistance, acrylic enclosures are often used around sensitive machinery. Such enclosures can come in many shapes and sizes for the complete machine or certain critical parts. For instance, a laser cutting device can be protected with a cylindrical lucite enclosure along the part that radiates light. So, light only falls on the intended product without harming humans or the environment. Lucite machine guards store machinery parts from insect or pest invasion, keeping them dust-free for longer durations.

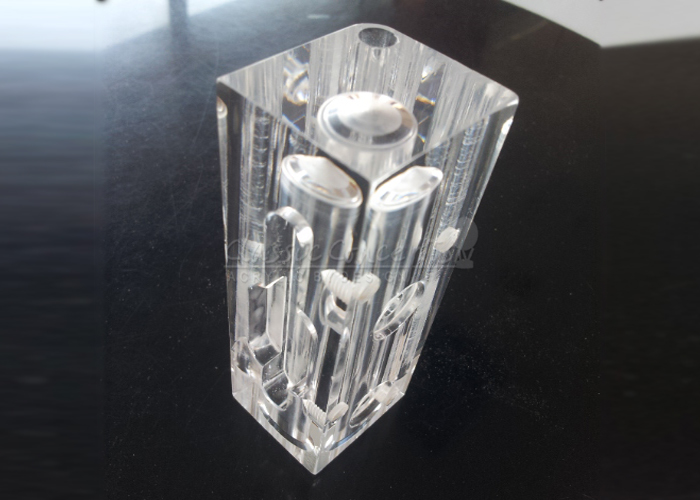

Transparent Acrylic Sheets

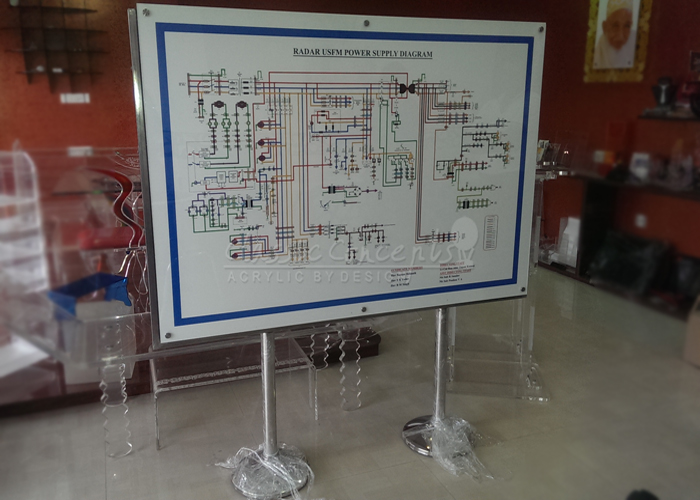

Transparent acrylic sheets are made by industrially pressing several layers of plastic in an eco-friendly manner. Acrylic sheets have versatile uses like glazing, fabrication, and protective barriers for industrial components. Thus, it won't be wrong to say that acrylic has redefined industrial engineering. Transparent acrylic panels are versatile industrial products used in various places like electricity junction boxes, touch screens for providing machines with inputs, doodle boards, etc. They can come in different thicknesses, sizes, and grades, like plexiglass or lucite. Plexiglass is another term used to define acrylic and is the most preferred material for curating industrial products that look like glass but do not break.

Acrylic Safety Shields

Safety equipment is mandated in all industrial manufacturing units and factories. Without the appropriate safety gear, industries can even lose their license. Acrylic industrial products meet all industrial standards for the safety of equipment and workers. Acrylic safety shields are employed in drilling to protect oneself from fire sparks and harmful UV lights. These shields can be designed to cover the face during chemical experiments. Certain parts of the machinery are protected from flying debris, airborne dust, and insect invasions. For machines radiating heat or smoke, acrylic shields can cover them to minimize temperature rise in the nearby environment.

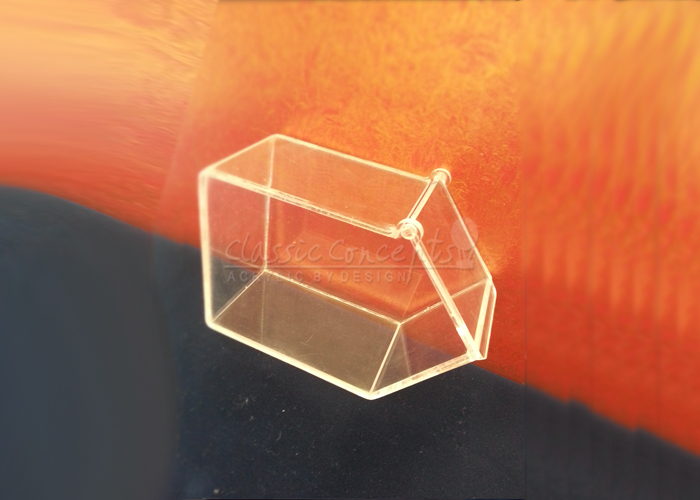

Plexiglass Laboratory Equipment

Earlier science labs in schools and colleges mostly had glass beakers, test tubes, and pipettes, making their breakage replacements a pricey affair. Acrylic laboratory equipment is easy to handle and can survive accidents without breakage. Also, plexiglass is resistant to heat and harsh chemicals. Acrylic is an excellent option for school laboratories and high-end medical and pharmaceutical labs. Acrylic products can be sterilized and reused without any infection spread. One can safely collect blood, urine, and other lab samples for medical tests with small acrylic storage units. Acrylic neither degrades over time with chemical exposure nor releases toxic chemicals. Acrylic is thus a sustainable choice for customized laboratory equipment.

Customization Options for Acrylic Industrial Products

Industrial innovation is a never-ending process. Every day, a new product or machinery serves a new requirement. Along with these come the safety standards, protocols, and operating guidelines. Plexiglass and lucite materials are safe and sturdy for use across various industries and as commercial products. Industries use transparent acrylic panels as a shield for various industrial components. They come in any shape and size that fits your machinery. We can print industrial safety guidelines on a large acrylic plaque for employees. The plaque comes in the desired size, fonts, and colors. Acrylic enclosures can safeguard electrical units and transformers within your premises. From storage solutions and safety equipment to visually appealing decorative products and transportation solutions, acrylic products cover them all. You can make customized soda bottle holders racked in neat acrylic shelves for easy transportation. Transparent acrylic sheets can be modeled into clear acrylic lockers for employees to store their safety equipment. You can also label the lockers with printed or laminated numbers.

Practical Considerations for Using Acrylic Industrial Products

Industries require all to adhere to the instruction manual strictly. Failing can result in serious accidents that can turn fatal. Before choosing the acrylic grade material, consider the industrial environment, its temperature, chemical exposure, and the purpose of use. Such factors play a crucial role in deciding the life of your acrylic industrial products. Though acrylic is durable, it is prone to scratches upon rough use. Fire sparks or flying debris can harm acrylic enclosures. Hence, it is essential to go for a higher grade of acrylic, like lucite for such sensitive areas. Industrial-grade acrylic products require professional cleaning and maintenance. Follow your manufacturer's maintenance instructions for a long shelf-life of your products. For small-scale usage in school or college labs, plexiglass laboratory equipment will suffice. However, add customized lucite laboratory enclosures in medical labs and pharmaceutical testing zones.

Conclusion

Acrylic is now a part of every sphere of life, and acrylic industrial products rule every possible manufacturing unit in our world. Industrial products include large storage solutions, connectors and conveying products, safety shields and gears, laboratory aids, and transparent raw materials that can further turn into numerous end products. Acrylic has several features that make it suitable for standards-based industrial usage. It is durable and resistant to breakage. Its malleability enables the cutting and shaping of various items like tubes, beakers, cases, enclosures, etc. Occasional maintenance (as per the instructions) specified by the manufacturer makes your acrylic products serve the intended purpose for extended periods. Look at our catalog of acrylic industrial products and the industries we cover. Reach back to us with your requirements, and we provide a cutting-edge design to solve all your needs.